Posted By: Andrew Kamashian | Posted On: Mar 24, 2023 12:00:00 AM

Bendmak B3DL 3 Spindle Drill: The Most Efficient in Structural Steel

The manufacturing and processing of steel beams for structural fabrication is a critical process in the construction industry.

The efficiency and accuracy of this process are vital for not only ensuring the structural integrity and safety of buildings and structures but also for the ease in assembly once these components are relocated from the shop to the field. The Bendmak B3DL 3-Spindle Drilling System is the most efficient machine for processing steel beams for structural fabricators due to its advanced features and capabilities which provide for an accurate beam, as designed in a system fully automated for maximum productivity.

The efficiency and accuracy of this process are vital for not only ensuring the structural integrity and safety of buildings and structures but also for the ease in assembly once these components are relocated from the shop to the field. The Bendmak B3DL 3-Spindle Drilling System is the most efficient machine for processing steel beams for structural fabricators due to its advanced features and capabilities which provide for an accurate beam, as designed in a system fully automated for maximum productivity.

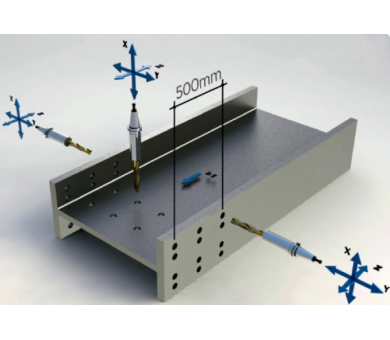

First, the Bendmak B3DL 3 Spindle Drilling System is capable of drilling multiple holes, simultaneously in steel beams with high precision and accuracy. The machine is equipped with three 3-Axis BT-40 30HP spindles that can not only drill holes simultaneously, but from 3 sides of the beam at once making it possible to drill multiple holes in a single pass. This not only reduces the processing time but also improves the accuracy of the drilled holes. Coupled with the capability to not only drill holes but to mill, tap, countersink and engrave makes this structural processing machine a powerhouse for any structural builder. The machine also has an automatic centering feature that ensures the holes are drilled in the correct position, further improving the accuracy of the process.

Secondly, the Bendmak B3DL 3 Spindle Drilling System is a highly efficient machine. It has high drilling speeds that can reach up to 1,200 RPM while being pushed by a powerful 30HP Drive, allowing it to drill holes quickly and efficiently with Solid Carbide, Insert or simple High Speed Steel Tools. Coupled with 3 Independent tool changers to service each of the B3DL's spindles allows for uninterrupted beam processing while the spindles switch tools for drilling, tapping, countersinking, milling and many other operations. The machine also has a powerful motor that can easily handle heavy-duty drilling tasks, making it ideal for processing steel beams of different sizes and thicknesses including I-Beams, Channels, Tubing, Angles and Plate.

Moreover, through the powerful and adaptable Mitsubishi Controller the machine is fully automated, which makes it easy to operate and reduces the risk of errors. The operator can easily input the drilling parameters into the machine's control panel, and the machine will automatically adjust its settings to ensure the drilling process is carried out accurately and efficiently. Driving 10 Axis in simultaneous productivity is no easy task but the Mitsubishi Control System makes this operation a breeze for the operator and programmer. This not only reduces the processing time but also improves the safety of the process as there is no need for manual intervention.

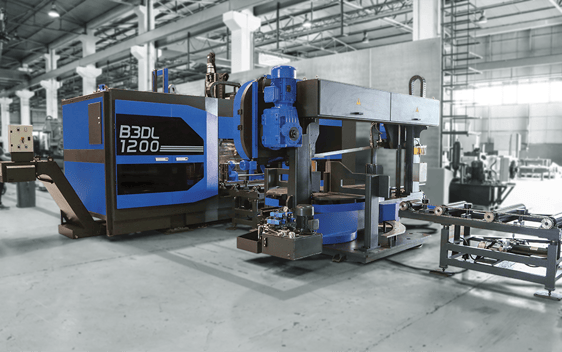

Another key advantage of the Bendmak B3DL 3 Spindle Drilling System is its versatility. The machine can handle different types of drilling tasks, including drilling holes of different sizes and shapes, milling of slots and even light coping operations making it suitable for a wide range of structural fabrication projects. The machine can also be customized from the 7-Axis B3DL ECO to the Powerful 10-Axis B3DL to meet the specific needs of a project, which makes it a highly versatile and adaptable system.

Another key advantage of the Bendmak B3DL 3 Spindle Drilling System is its versatility. The machine can handle different types of drilling tasks, including drilling holes of different sizes and shapes, milling of slots and even light coping operations making it suitable for a wide range of structural fabrication projects. The machine can also be customized from the 7-Axis B3DL ECO to the Powerful 10-Axis B3DL to meet the specific needs of a project, which makes it a highly versatile and adaptable system.

The B3DL takes the concept of productivity even further by including a strong and reliable beam clamping/motion system which ensures the segment being processed will be in the right place for processing by the 3 spindles or other accessories and attachments. Adding to that productivity is the ability to customize the B3DL with automatic loading and unloading devices as well as integrated mitering sawing all programmable though the powerful yet simple Mitsubishi Controller.

Finally, the Bendmak B3DL 3 Spindle Drilling System is a highly reliable machine. It is made of high-quality materials and has been designed to withstand the heavy-duty demands of the structural fabrication industry. Equipped with the most robust drives and electronics available provide for an unmatched reliability and serviceability in the structural machine market. This incredible design is further enhanced with the latest in safety devices ensuring the operators and maintenance personnel are safe from injury during normal operation. Adding ease of maintenance ensures its longevity and reliability.

Finally, the Bendmak B3DL 3 Spindle Drilling System is a highly reliable machine. It is made of high-quality materials and has been designed to withstand the heavy-duty demands of the structural fabrication industry. Equipped with the most robust drives and electronics available provide for an unmatched reliability and serviceability in the structural machine market. This incredible design is further enhanced with the latest in safety devices ensuring the operators and maintenance personnel are safe from injury during normal operation. Adding ease of maintenance ensures its longevity and reliability.

The Bendmak B3DL 3 Spindle Drilling System is the most efficient, easiest to use and maintain, machine for processing steel beams for structural fabricators. Its advanced features and capabilities, including high precision and accuracy, high drilling speed, full automation, versatility, and reliability, make it an indispensable tool for the construction industry. By investing in this machine, structural fabricators can improve their productivity, efficiency, and accuracy, and deliver high-quality steel beams that meet the industry's standards and requirements.