Posted By: Andrew Kamashian | Posted On: Apr 14, 2023 12:00:00 AM

Understanding the Differences in Beam Drilling Systems

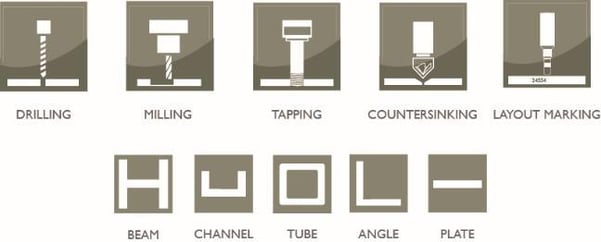

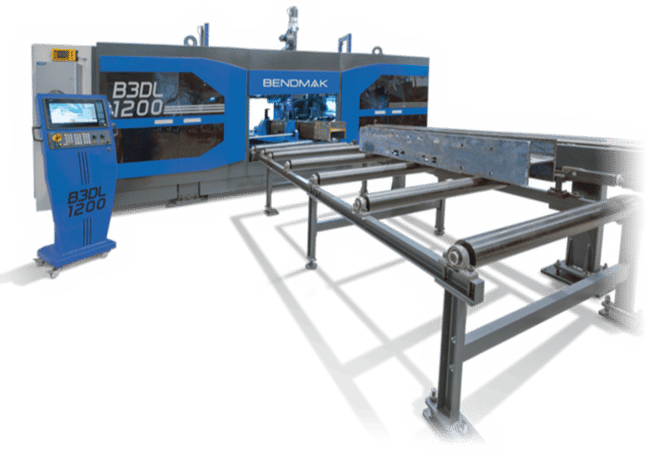

Beam Drills are one of the most necessary systems in the structural fabrication shop for producing detailed beams in a timely and efficient manner. These systems take the guess work out of holes, slots or a variety of other features in structural beams and provide exacting connecting points for a much easier assembly in the field. Beam Drills, like many other processing systems can be equipped with a variety of options and capabilities to make them more efficient, faster, easier to use or scaled back to make them more affordable for the entry level user. Whichever Beam Drilling System you choose, from the robust and capable 10 Axis B3DL to the space saving and robust 3 Axis B1DL BendmakUSA has the right system for you.

Below we will dive in to what's the difference between these powerful drilling systems, what are their capabilities and what offsets one from the other.

Single Spindle Drilling Systems - The Bendmak B1DL

The Bendmak B1DL Drilling system is an economical solution for entry level or space saving structural fabrication shops. Taking minimal floor space this machine hold the beam from 8'-85' lengths on a sturdy table that doubles as the drive system for the drill head. Capable of accurately detail drilling, engraving, countersinking, tapping and so much more, this powerful system drives itself down the length of the beam and then clamps into position securely holding the beam in place while the powerful 20HP drilling head does the work moving vertically up the entire face of the beam. Utilizing its standard 6 Station Tool Changer the operator merely monitors the machine while it precisely and accurately delivers hole after hole and detail after detail. Repositioning down the beam the BIDL makes short work of even the most detailed Beams, Pipe, Angles, Channels, Squares, Flats or just about any other shapes capable of fitting into its giant window of capability.

Just a few of the unique advantages of the B1DL by Bendmak are:

- Fast return on investment

- High versatility in small footprint

- Fully CNC control

- 20 HP spindle motor power

- 6 Station tool changer

- LASER automatic tool measurement & material zero referencing

- High positioning tolerance and repeatability

- Very robust design

- Worldwide spare parts availability

- User friendly interface

- Fast, accurate and maintenance free

- Available in lengths of 20, 30, 45, 60, 70 & 85 Feet

The B1DL Is also further enhanced with an optional & affordable beam flipping device providing capability to completely process all sides of a structural component without operator intervention. This powerful option allows just one operator the capability to completely access and process all sides of the structure being processed.

3 Spindle Economical Drilling Systems - The Bendmak B3DL ECO

Bridging the gap between the single spindle drilling systems and superior versatility of the 10 Axis+ Beam drilling system is the very capable 7-Axis B3DL ECO by Bendmak. This system utilizes a beam clamp, pushing device to move the beam or other structural component through the machining area where 3 spindles simultaneously attack and devour enormous amount of material creating a detailed profile 3X faster then the B1DL can do. In the ECO the beam is moved along the longitudinal axis to each position necessary for processing where 1-3 Powerful 30HP Drilling Heads process the part as needed with tools up to 1.57" in diameter. As the B3DL ECO processes the beam from all sides the beam does not need to be rotated saving additional processing time over the B1DL.

Adding to the B3DL ECO's cap[ability is the 3 independent 4 position tool changers that can be loaded with a variety of tools for beam processing including both HSS and Carbide Drills, Countersinks, Taps, End Mills, Scribing Tools and a Variety of other Processing Tools. More key advantages of the B3DL ECO include:

- Chip Conveyor for efficient scrap removal

- Optional Integrated Mitering Band Saw

- Automatic Cross section Measuring

- Optional Tapping Tools on all 3 Axis

- MQL Tool Lubrication system for all 3 Tools

- Central Lubrication

- Motorized Exit Table

- CNC Driven Infeed

- Automatic Tool Changers on all 3 Spindles

- 206 LBS of Spindle Torque per Spindle

- Powerful yet easy to use Mitsubishi CNC Controller

All of these standard and available optional features make the B3DL ECO an excellent choice in beam processing.

3 Spindle 10 Axis The Ultimate in Beam Processing - The Bendmak B3DL

For maximum efficiency and speed in beam processing is the Bendmak B3DL system. This machine provides not only all the capability of the B1DL and B3DL ECO but adds to it 10-Axis capability. With the additional 3-Axis over the ECO model the B3DL creates a "Window" of processing with the 3 powerful 30HP spindles. This capability allows for each of the 3 spindles to work on any variety of the beam within its reach in a 48" X 20' X 20" .

Options That Increase Performance of Your Beam Drill Line

Once you have decided on the right Bendmak Beam Drilling System for your needs it's time to select all the options that will further increase your productivity. Options like:

- Beam Transfers which automatically load the beams onto and off of the machinery for processing.

- Beam Flipper (B1DL only) to rotate the beam for processing on all sides.

- Integrated or Stand Alone Miter Sawing

- Integrated Plasma Coping

- Tooling Packages

- Engraving Options

Whatever Bendmak Beam Drilling System you choose you'll be headed in the right direction. With a Drilling Line and an Angle Line like our BEAP Angle Punching & Shearing System our fabricators will have to work fast to keep up with the productivity of quality parts coming off of these systems. Add to and increase your shops capability the Bendmak way.