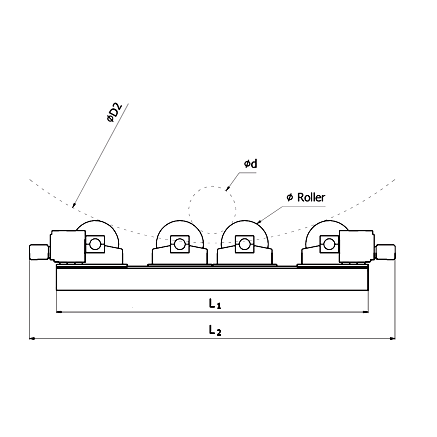

Machinery CR Conventional Tank Rolls Tank Rolling Systems

Machine Features

Request Information

CR Conventional Tank Rolls

Conventional type tank rolls are a quality and economical solution product in environmental welding of cylindrical parts where the diameter is not variable. It is used for rotating circular parts such as tanks, pressure vessels, tower pipes, boilers, tanks, reactors, fuel barrels.

Tank Rolls increase the speed and efficiency in both automatic and manual welding and have an important place in steel construction workshops by minimizing the use of cranes.

Operators; They can rotate the pieces they put on the tank rolls clockwise or counterclockwise, precisely, smoothly and at an adjustable speed that they can control over the control panel.

Set of conventional type tank rolls; It consists of two units, 1 driven and 1 idler. The number of driven and idle units may vary depending on the application.

Bendmak includes 1 to 300 tons conventional tank rolls in its standard lists. However, in special cases, it has the capacity to produce up to 600 tons.

- Impact and shock resistant "PU" wheels

- Manual diameter adjustments

- Adjustable rotation speed

- Remote control with a 15' cable

- Digital speed indicator on the control panel for tracking the turn

- Brake motors

- Special wheel designs for high temperature applications

- Axial Stop

- Chassis - Brush Group

- Rail Movement System (Carrier Car System)

- Synchronous operation feature with column boom systems

- Rail

- Automatic diameter adjustment - Motorized