Machinery SRH Series Hydraulic Welding Positioner Welding Systems

Machine Features

Request Information

SRH Series Hydraulic Welding Positioner

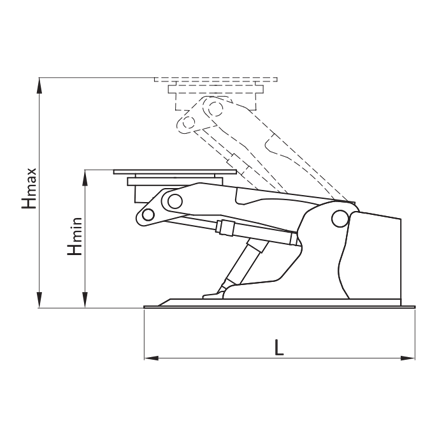

The structure of Bendmak hydraulic welding positioners is designed for the most accessible configuration for rotation and angular tilting of the table.

Unlike other positioners, these positioners can be adjusted in height while working on the piece. Thus, operators can work more comfortably and thus, effectively.

With the positioner, regardless of the geometric shape welded, all parts within the size range can be positioned and a suitable welding position can be achieved. Positioners increase speed and efficiency in automatic, robotic and manual welding and have an important place in steel fabrication workshops by minimizing the use of cranes, forklifts etc.

Construction; It consists of frame, motor, table rotation and tilt systems, electrical panel and remote operator control unit and has the best structural protection. (Note: Positioners for heavy workpieces must be bolted to the floor.)

Operation; Operators can rotate the parts they put on the rotary table in the positioner clockwise or counterclockwise, precisely, smoothly and at adjustable speeds that they can control over the control panel. They can also tilt forward to provide the desired angle.

Clamping; There are standard "T" Slots on the rotary table. In this way, it enables fast clamping of the workpiece. Table rotation and tilting are driven by a powerful steel spur gear transmission system.

%20New%20Bendmak%20SRH-1000%20Hydraulic%20Welding%20Positioner%20-%20Pic%202.png?width=588&height=439&name=(5379)%20New%20Bendmak%20SRH-1000%20Hydraulic%20Welding%20Positioner%20-%20Pic%202.png)

- Adjustable rotation speed

- Remote control with 15' cable

- Digital speed indicator on the control panel for tracking the turn

- Brake motors

- Mechanical angle indicator (in tilt movement)

- Programmable automation control (plc)

- Wireless remote control

%20New%20Bendmak%20SRH-500%20Hydraulic%20Welding%20Positioner%20-%20Pic%202.png?width=842&height=280&name=(5127)%20New%20Bendmak%20SRH-500%20Hydraulic%20Welding%20Positioner%20-%20Pic%202.png)