Machinery BMB-P Dishing Press Dishing & Flanging Machinery

Machine Features

Request Information

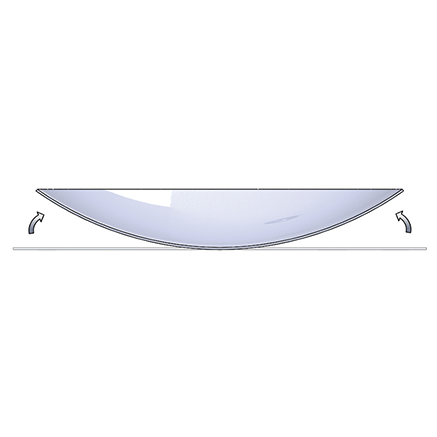

BMB-P Dishing Press

The Best Design for Tank Builders

Bendmak shows its experience in all areas of metal processing and forming. Bendmak, which researches high quality solutions for the doming industry, is also a leader in this field with its BMB dome presses and edge flanging machines. This line of presses has been specifically developed for the needs of pressurized tanks, boilers, food silos, power plants, petrochemical plants, aviation and shipyard industries.

The BMB-P Dishing Press, along with our other models are one of the most demanded models among the wide Bendmak product range. It is a hydraulic press working with automatic rotator/manipulator and developed for heavy condition. Producing 150 to 1600 tons of power onto 20" to 32' inner diameter shells this powerful pressing system easily accomplishes the most difficult tasks. Considering that the main goal of all tank manufacturers in the world is maximum price vs performance, models of 250 tons and above are equipped with pre-tensioned rods, and the models under 250 Tons are designed as column overlap style press.

Suitable capacity is determined depending on the material quality, thickness and diameter of the blank.

The pressing force of the BMB-P models are engineered for the lowest cycle time and highest productivity and are calculated considering the largest die diameters.

The main control screen is designed for the easiest learning and use, in order to assist our customers using inexperienced operators.

The pressing force of the BMB-P models are engineered for the lowest cycle time and highest productivity and are calculated considering the largest die diameters.

The main control screen is designed for the easiest learning and use, in order to assist our customers using inexperienced operators.

- Body construction is high alloyed steel and mig welded.

- The body has been subjected to stress relieving in order to be processed with much narrower tolerances after welding.

- A special primer is used before painting for corrosion resistance of the whole frame.

- There are ladders and safety barriers that allow maintenance personnel to safely access the press.

- Hydraulics: Cylinder, body and piston group are not only heat treated but also chrome plated for long life and wear resistance.

- Lubrication points have been minimized by using maintenance-free components throughout the design.

- The controller provides easy control of the cylinder and the manipulator allow it to stop at any position as well as manages any warnings and alarms for all systems.

- Process time of a workpiece is shortened by utilizing much larger die diameters by up to 50% compared to crowning with a smaller diameter mold.