Machinery 3-Roll Variable Geometry Plate Rolls

3-Roll Variable Geometry

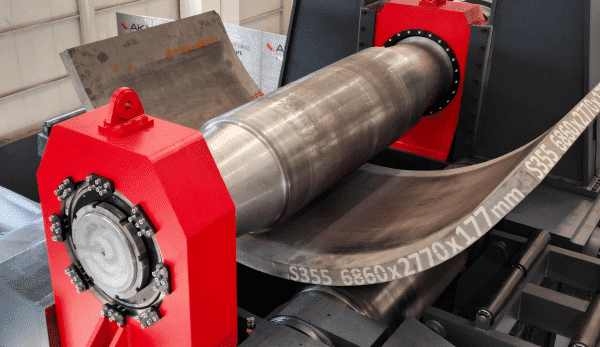

The BENDMAK BHV is a powerful and adaptable machine with a design that allows three rolls to move independently from one another. The BHV has a top roll that moves vertically and side rolls that move horizontally, ensuring they can achieve the necessary positions to handle complex designs that require varying thicknesses and curves.The BHV offers remarkable versatility when it comes to manipulating thick metals. It's designed to provide the capacity to tailor production through precise rolling with asymmetrical roll positioning, minimizing the production of flat ends. This precision allows for greater flexibility in shaping and finishing. Similarly, for situations requiring maximum thickness rolling, the BHV can use symmetrical roll positioning, making it a reliable solution for various manufacturing needs.

Strength and Flexibility

The strength of the BHV lies in its robust design to handle a variety of materials and thicknesses, while its flexibility lies in its variable geometry system which enables it to cater to a variety of bending diameters and shapes.

Precision and productivity

For maximum thickness bending, the rolls can be positioned symmetrically on both sides, while for the straight ends, the rolls can be positioned asymmetrically to perform precise bending.

Robust Body

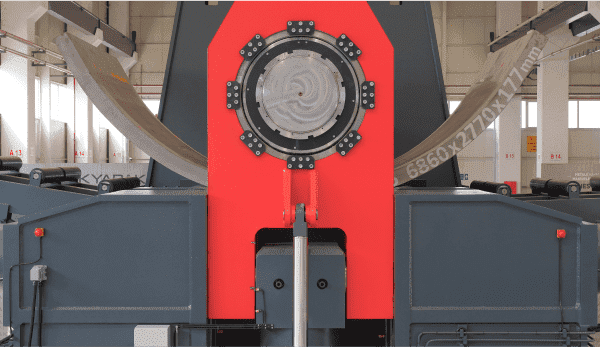

The structure of BHV is designed using Finite Element Method (FEM) analysis and is built to have optimal strength and rigidity. As a result, the bending stresses are significantly reduced, ensuring safer operation and a prolonged machine lifespan.

Electronic Parallelism

The BENDMAK electronic parallelism control system is designed to deliver accurate and consistent results in rolling operations. Its longevity is ensured by its precision maintenance capability. It uses proportional valves managed by a PLC system to maintain balance and allow communication between the rolls.